Have you ever wondered what the four fundamentals of safety requirements are for elevator technicians and builders? " The majority of job-related injuries experienced by elevator technicians, constructor mechanics, and apprentices are brought on by diversions, complacency, overconfidence, incomplete or inadequately worn personal protection equipment (PPE), a lack of safety training, or distractions. Safety must always come first when working on conveyance machinery, whether it's an elevator or escalator. Before starting any work on a job site or particular task, it is crucial to check all PPE and items in your safety bag and go over all the procedures and processes, especially if the work will be done in confined spaces (including confined spaces that require a permit), at elevated heights, or in close proximity to nearby equipment, high voltages, and hazardous chemicals or materials.  photo credit: Alex_u via GettyImages FALL PROTECTION An anchorage point, a body harness, and a lanyard make up the three primary components of the Personal Fall Arrest System (PFAS). It is the standard PPE that elevator technicians, construction mechanics, and apprentices are required to wear while they are working in an environment where a fall of at least 4 feet (in general industry) or at least 6 feet (in construction) is possible. Always make sure to use your lifeline or other anchoring devices in accordance with the user's manual, Occupational Safety and Health Administration (OSHA) Regulations and Standards, and your company's policies and procedures. These materials' reading and comprehension could mean the difference between life and death. When it comes to workplace risks, falls rank first on OSHA's "Focus Four" list, which lists the four most frequent reasons for worker fatalities on construction sites. Falls account for 33.5% of worker fatalities.According to OSHA, the most frequent safety violation that resulted in accidents and fatalities in 2021 was inadequate fall protection. Along with safety nets and common guardrails, fall protection equipment can save your life. Before beginning any maintenance on an elevator, escalator, or other sort of conveyance equipment, use caution and take the time to thoroughly inspect each component of fall prevention equipment. photo credit: Pakorn_Khantiya via GettyImages EYE AND FACE PROTECTION Eye or face protection that is insufficient or worn incorrectly is involved in eight of the top 10 OSHA rules that are often broken. Eye and face protection must always be carried by elevator technicians and builders in their safety bags to prevent injuries from cutting, welding, dust, dirt, and other objects. Each year, thousands of construction workers lose their eyesight; many of these accidents could have been avoided if the proper eye and facial protection had been used. To keep safe when working, always put on your safety glasses, goggles, face shields, and welding helmets (if necessary). photo credit: Kali9 via GettyImages LOCKOUT/TAGOUT (LOTO) / TEST AND VERIFY (MECHANICAL ENERGY) In order to prevent electrified equipment from turning on while elevator workers or builders are working on it, lockout/tagout (LOTO) and test and verify procedures are used. Workers are shielded from electrical energy as well as other forms of stored energy by LOTO methods. In the elevator sector, typical LOTO operations can involve employing rope grippers on traction equipment or pipe stands to maintain an oil column holding up hydraulic equipment. You must always lockout, tagout, test, and confirm your equipment to remove the stored electrical, mechanical, gravitational, hydraulic, or pneumatic energy unless you are working on a system that must remain energized while troubleshooting, and taking the precautions required by code and your elevator company's safety policies to do so. Lockout devices, such as keyed or combination locks, stop equipment from starting or moving after they are installed. Tagout devices are labels that are firmly fastened to equipment to show that both the equipment and the energy-isolating device are out of commission and to offer contact details for the person who locked out and tagged out the equipment. When an elevator's machinery has many isolation points, a group lockout box, also known as a LOTO box, or group lockout device must be employed before the equipment can be properly locked out. On OSHA's list of the standards that were most frequently broken in 2021, the absence of control over hazardous energy came in seventh. The administration reports that electrocution, scalding, and burns are the three most frequent workplace injuries caused by LOTO misuse. photo credit: Andrey Popov via GettyImages LOTO / TEST AND VERIFY (ELECTRICAL ENERGY) Elevator builders and technicians frequently use electricity while performing their tasks. Third on OSHA's "Focus Four" list, electrocutions cause 8.5% of fatalities among construction workers. Always check that the equipment you are working on is grounded, lockout/tagout any electrical equipment you are working on, and test and verify it in line with local, state, and national code requirements as well as your company's policies and procedures. Wear PPE that has received OSHA approval if you are installing or maintaining AC/DC equipment so you are protected from electrical risks. CONCLUSION

Always conduct a risk assessment of the workplace's potential physical or health dangers before beginning any elevator installation, modernization, repair, or maintenance procedures and make sure that you and your coworkers are aware of what has to be done to reduce your risks. While it is the obligation of your employer to supply you with the right safety equipment, training, and PPE, you are still responsible for understanding how and when to use it and making a commitment to doing so consistently. Members receive fundamental elevator constructor safety training from organizations like the National Elevator Industry Educational Program (NEIEP) and the International Union of Elevator Constructors (IUEC), which offers OSHA-certified courses on the most recent tools, processes, and techniques. One of the best benefits that the IUEC, its union-affiliated employers, and NEIEP provide to all elevator constructor mechanics and apprentices is safety training. (Employers are obligated to offer more thorough safety training.) The general duty provision of OSHA encompasses both employee and employer obligations.

0 Comments

Tags:

(photo cred: Golib via Canva Pro) Prior to the COVID-19 pandemic, the things that consumers and producers desired, from cars to toilet paper to yeast to lumber, simply appeared in showrooms, store shelves, and ports to be purchased and used whenever it was convenient. However, over the last 18 months, we've seen shortages in both large and small quantities, often caused by surprisingly minor causes and hidden vulnerabilities. For example, demand for yeast quadrupled in spring 2020 as homebound Americans experimented with breadmaking. Fleischmann's Yeast, a major producer, had the capacity to produce yeast; however, a lack of packaging caused shortages and delays. The glass jars used to package the yeast came from India, where manufacturing had been halted due to the COVID-19 pandemic. Some of these shortages were quickly resolved by nimble businesses. Fleischmann's discovered how to package yeast in plastic bags, and toilet paper manufacturers made a slew of minor changes to their equipment and product mix. Others, such as the semiconductor chip shortage, have proven more difficult to resolve and are weighing on the US economy. According to some analysts, the chip shortage could reduce GDP growth by nearly a percentage point this year, and it has resulted in waves of production shutdowns that have harmed hundreds of thousands of U.S. workers employed in manufacturing jobs in the automotive and heavy trucking sectors. A resilient system has the ability to recover quickly from an unexpected shock. Firms often use three interconnected strategies to strengthen resiliency in manufacturing supply chains: Visibility: The ability to monitor the supply chain, often in real time. Buffering: Having multiple sources of supply or holding more inventory. Agility: The ability to quickly pivot to alternative processes or products. Individual firms' ability to pivot quickly in the face of a shock, on the other hand, can be limited by collective action issues, such as a lack of communication and trust between firms along a supply chain, and a lack of access to the data required to support visibility and agility. The government has an unrivaled ability to solve coordination problems and serve as a reliable source of data. This role is especially important during times of scarcity because it counteracts the tendency of downstream firms, such as manufacturers of finished goods, to overorder or hoard inventory and of upstream firms, such as manufacturers of inputs, to not fulfill orders due to a lack of trust in the demand signal, resulting in shortages, delays, price increases, and uncertainty for the workers, families, and small businesses who rely on these goods. Reaffirming Our Commitment to Transparency and Flexibility Since April, the Administration has used its convening power to improve communication and trust between semiconductor manufacturers (including those that design chips, manufacture wafers, and assemble them into devices) and semiconductor users (including automakers, consumer electronics manufacturers, and medical device manufacturers). As a result, firms such as General Motors have changed their supply chain management practices, announcing new efforts to build more direct working relationships with semiconductor suppliers who are downstream suppliers to GM. It also includes chip manufacturers' growing recognition that industrial sectors such as the automotive industry represent a growing customer base. This is a step forward, and we continue to look to industry to take additional steps to improve transparency, trust, and accountability to help address bottlenecks in the supply chain. In order to diagnose supply chain chokepoints and provide businesses with information that can help them adapt their production processes to the supply shortage, the Department of Commerce is currently taking new steps to improve data collection. This includes conducting a voluntary survey of industry participants. For instance, the survey may reveal that power management chips are not in low supply, but sensors used in sensors that help trigger pacemakers and power a car's safety features. In this approach, the data can also serve as a distinct demand signal, luring more private capital to increase production and alleviate the shortfall. Additionally, in order to address the shocks to global supply chains brought on by the COVID-19 pandemic, we have been collaborating with foreign governments in Southeast Asia and other regions to maintain the operation of crucial factories while putting worker health and safety and our trading partners' public health responses at the forefront of our efforts. By setting up a new early alert system for COVID-related shutdowns of microelectronics manufacturing globally, the Biden-Harris Administration is building on this work. The system will help us identify possible problems sooner, assist quicker problem-solving, and coordinate with the private sector and our trading partners while balancing a focus on worker health and safety, supporting the public health response, and safely reopening factories. Also, this system is made to safeguard confidential or proprietary information for businesses who freely participate. The entry point for business will be the Commerce Department, which will collaborate closely with the State Department both in Washington, D.C., and at our embassies abroad. To complete this goal, we will also rely on technical specialists from the CDC and USAID. Avoiding the Next Chips Shortage Yet, in the long run, the U.S. needs to act more forcefully to spot and prevent weaknesses in the supply chains of vital goods. Shocks in the supply chain are not uncommon. According to a McKinsey Global Institute report, supply-chain shocks with an impact on global production lasting at least a month happen roughly every 3.7 years on average, costing businesses 42 percent of a year's revenues. Due to an increase in the severity and frequency of storms, droughts, and other extreme weather events, the climate crisis is driving "100-year" events that interrupt supply chains to occur more frequently and with more ferocity. If we don't take action to create more robust supply chains throughout the public and private sectors, as well as with partners and friends, American workers, consumers, and companies will continue to experience disruptions and price shocks. Since taking office, the President has responded quickly and consistently to supply chain risks. In February, he issued orders for a 100-day supply chain evaluation of a few key items and a one-year supply chain vulnerability analysis for a few key industries. A strategy for reducing supply chain risks by putting money into American workers, communities, and innovation is laid out in the 100-day report, which was released in June. Additionally, it argues for the creation of new federal tools to address these vulnerabilities. This includes the ability to map and monitor current gaps and run stress tests to identify potential vulnerabilities. It also includes funding for applied research on best practices for supply chain resiliency at the firm and national levels. Finally, it includes financial tools like grants and loans to advance private sector investments in resiliency, combating the tendency of the private market to overinvest in short-term cost control and underinvest in resiliency. Congress may advance the development of more resilient supply networks by taking two essential actions. The bipartisan CHIPS for America Act, which would allow for transformative investments in domestic semiconductor research, design, and production, may be funded first by Congress. The long-term answer to the current chip scarcity is this. Second, as part of his Build Back Better proposal, which is currently being considered by Congress, President Biden has proposed the new Critical Supply Chain Resiliency Program (CSCRP) at the Department of Commerce. The program would serve as a central node in the federal government for supply chain resilience, facilitate better coordination and planning across federal agencies to address vulnerabilities, and invest in critical supply chains where the private market has failed to allocate sufficient capital. The following are a few examples of the activities the new office could support: The U.S. government is attempting to avert interruptions in the supply chains for cutting-edge energy and communications equipment by mapping the supply chains for essential businesses. Along with industry partners, the CSCRP surveys businesses in each sector. The office can undertake stress testing for various shocks thanks to the survey's data and mapping, this includes scenario planning exercises, for example, a cyber assault at a vital node, to help the private sector and government agencies be better prepared to react to potential shocks to a crucial supply chain. Developing domestic clean energy supply chains: A U.S. consortium of green energy businesses wants to bring the supply chain for solar panel production domestically. Currently, Chinese companies manufacture 80% of the world's solar panels, in part because of Chinese government subsidies. The CSCRP offers low-cost financing to encourage the establishment of new U.S. manufacturers in order to increase the proportion of American-made renewables in the projected U.S. build-out. Increasing the availability of reliable and secure hardware: A prospective 5G equipment start-up is looking to increase production of 5G network infrastructure equipment. But, it has had difficulty obtaining the late-stage finance necessary to commercialize its technology, a long-standing issue that has driven numerous American manufacturers overseas. A contract manufacturer is wooing the business to relocate its production to Asia. In order to solve this problem, CSCRP offers a direct loan for a portion of the scale-up requirements and a loan guarantee for the remainder. The federal government needs to be better prepared to anticipate potential disruptions and have the resources at its disposal to lessen their effects on the American workforce, customers, and economy. One company or industry cannot predict or appropriately address the impacts of a cascading supply chain shock on the global economy on their own. The federal government can monitor, foresee, and react to economic, geopolitical, and climate-related shocks by taking a comprehensive approach to the industrial base and supply networks that are essential to US economic and national security. In order to boost our country's long-term economic competitiveness, our national security, and to advance the President's 21st century industrial plan, the CHIPS Act and the CSCRP are two crucial initiatives. Preventing the next global supply chain catastrophe in the first place is the key to solving it.

Tags:

(sourced: Pexels by Guillaume Meurice) Modernizations and new installations will be significantly impacted by amendments to the NYC Building Code and the Elevator and Escalator Code that took effect on November 7, 2022. Owners that are thinking about updating/altering or installing new vertical transportation equipment should get in touch with the VDA Consulting Office to discuss these impending changes. Furthermore, affected are projects that are currently under contract but may or may not have all necessary permits obtained and issued by November 7, 2022. It is advised to speak with your VDA Elevator Consulting contact as soon as possible. Notwithstanding the lengthy list of revisions to the Code, the following are only a few extracts that will have an influence on construction and elevator modernization projects:  (sourced: Unsplash by Kirklai) The Vehicle's Permanent Two-Way Communication Mechanisms Adjacent to the "PHONE" pushbutton on the same panel:

Elevators That Are Destination-Oriented Hall call console number and provision: According to Section 1109.7.2.1.1 or 1109.7.2.1.2, as appropriate, hall call consoles (input devices) must be located and provided in a number. One console for each type of use at each separate location must be situated on an accessible route leading to the elevator landings that are served by all such consoles, with the following exception: if hall call consoles are a necessary component of security barriers.

(sourced: Unsplash by Lucian Alexe) These are only a handful of the modifications to the Code that could affect your project. These are simply extracts and do not encompass the full of a change to the entire Code or a particular portion.

Tags:

(sourced: loving-newyork.com)When Fred Jung first noticed it, he was in East Rutherford's American Dream megamall. An elevator that leads to nowhere. Jung recently noticed the vehicle while he was on the third floor of the shopping center next to the food court. This escalator leads to the fourth floor, and there are stairs in between. (sourced: NJ.com)The issue? The fourth floor doesn't exist. Jung chuckled. "Laugh at the foolishness of lost resources from poor planning and overpromising," he told NJ Advance Media. Yes, this would make the ideal backdrop for a barefoot David Byrne dance number, ala "American Utopia" on Broadway. But where exactly were the escalator and stairs supposed to lead? (sourced: NJ.com)Jung, a Fort Lee resident, posted a picture of the mall oddity on Facebook on Monday. He wrote in the post, "In the American Dream Mall, they have finished escalators and staircases that go nowhere. Clearly chose not to install that fourth floor. Some people have theorized that the escalator and steps were built to transport mall visitors to a false movie theater complex. Or one that was intended to exist but was abandoned due to the COVID-19 pandemic. When NJ Advance Media questioned Jessica Griffin, a spokeswoman for American Dream, about the escalator to nowhere, she declined to address the idea of a movie theater. She did mention the stairs and escalator, though, which had no destination. Griffin stated in an email that this land was set aside for a potential expansion of the entertainment industry. She stated, "As American Dream continues to deliver on its promise to become a world-class entertainment, retail, and eating destination, we hope to announce further entertainment uses shortly." The initial plans for this "world-class entertainment" did, however, include a posh movie theater. (sourced: bigscreen.com)Griffin stated in an email that this land was set aside for a potential expansion of the entertainment industry. She stated, "As American Dream continues to deliver on its promise to become a world-class entertainment, retail, and eating destination, we hope to announce further entertainment uses shortly." The initial plans for this "world-class entertainment" did, however, include a posh movie theater. Although not part of the compound for retail and entertainment, Bergen County was home to the first CMX cinema in New Jersey. At Closter Plaza on Vervalen Street in Closter, CMX Market Cinemas debuted in 2018. (sourced: businessyab.com)Griffin stated in an email that this land was set aside for a potential expansion of the entertainment industry. She stated, "As American Dream continues to deliver on its promise to become a world-class entertainment, retail, and eating destination, we hope to announce further entertainment uses shortly." The initial plans for this "world-class entertainment" did, however, include a posh movie theater. Although not part of the compound for retail and entertainment, Bergen County was home to the first CMX cinema in New Jersey. At Closter Plaza on Vervalen Street in Closter, CMX Market Cinemas debuted in 2018. In 2020, as the epidemic forced movie theaters to close worldwide, CMX applied for Chapter 11 bankruptcy protection. The same year, Triple Five and subcontractor Phoenix Diversified Group were sued by Avon Brothers, the Wall Township subcontractor hired to work on the CMX theater at American Dream, alleging unpaid $149,000. Subcontractor New Jersey Boom & Erectors claimed it was due $1.6 million in relation to the theater project when it sued Ameream, the Triple Five entity that owns the mall, Phoenix Diversified Group, and CMX Cinemas in 2021. The Closter theater was acquired by Landmark Theatres, which later reopened it as Landmark Closter Plaza, the company's first theater in New Jersey, last September. The mall doesn't appear to give any attention to the escalator that leads nowhere at American Dream. The colorful aircraft that dropped from the roof into a pool on February 19 at its DreamWorks Water Park has garnered more attention than less urgent issues, hurting four people. #elevators #projectmanagement #buildings #technology #innovative #gogreen #elevatorrepairTags:

(sourced: Thx4Stock via Canva) Arduino software and boards (hardware) made electronics development effortless over the years. With the aid of additional parts, this set facilitates the construction of interactive and digital gadgets. WHAT DOES ARDUINO INTEGRATED DEVELOPMENT ENVIRONMENT DO? Well...In order to write a code, a code editor is required. A compiler is then required to translate that written code into binary files aka a machine code; which the microcontroller then can understand. Programming software is also required in order to load those firmware files to the microcontroller. An Integrated Development Environment is simply known as Arduino Software which is what we refer to when we are combining all of these functionalities with extras like console support, debugging support, etc. The development IDE that is suited for Arduino boards is known by the moniker Arduino IDE. It has a compiler, code editor, serial console, programmer, serial plotter, as well as many other capabilities that are fully featured. Write, compile and upload code to practically all types of Arduino Modules using the Arduino IDE, an open-source program created by Arduino. cc. (sourced: Thx4Stock via Canva) INSTALLING THE ARDUINO IDE To obtain the most recent edition of Arduino IDE, you can download here. For several operating systems, including Windows, Linux and Mac, there are numerous versions available. In addition, there are two versions of the ID; 1.x and 2.x. For this example, we'll focus on the Classic 1.X Version. Both offer nearly identical functionality having it's different GUI and a few extra capabilities, including automatic code completion.

(sourced: Thx4Stock via Canva) CHOOSING THE APPROPRIATE BOARD ON THE ARDUINO Before compilation, it's crucial to choose the correct board since this compiler will utilize it during the the compile instructions. To accomplish that, choose your board out from the list by clicking on "Tools", "Board" and then "AVR Boards". CHOOSE ARDUINO SERIAL PORTS It's also crucial here to choose the correct serial port for the Arduino boards connection. You will not have the ability to upload this code to your board if you don't do this. To achieve that, pick the appropriate COM port by clicking on "tools" and then "port." Disconnect your Arduino board from the USB port then revisit the menu if you have several COM ports available and you're unsure of the one to use. This COM port which vanished will really be the right COM port. Select this USB port by reconnecting the board. DIFFERENT SECTIONS OF THE ARDUINO IDE There are three basic divisions of the IDE environment. These include menu bar, the text editor and the output pane. The Menu Bar: This top bar offers five options - file, edit, sketch, tools and help. File: With this option, you can create a brand new window or reopen an existing one to write the code. Edit: Used to copy and paste the code plus additional font modifications. Sketch: used for programming and compiling. Tools: Primarily employed in testing projects. A bootloader is burned to the fresh microcontroller using the programmer part of this panel. Help: If you're unsure about the software, full assistance is offered, from starting up to troubleshooting. The Text Editor: Underneath the menu bar, this tool serves for entering the necessary code. Output Window: The output pane at the bottom of the main screen, which mostly displays the memory usage and programming mistakes, is referred to as the compilation state of a running code. Before uploading this hex file to the Arduino Module, you must correct those problems. Arduino Board Types - Arduino Uno, Lilypad Arduino, Arduino Mega, Arduino Leonardo, Arduino Red Board, Arduino Shields. (sourced: Ibrar Hussain via Canva) CONCLUSION

By now, you understand what the Arduino Integrated Development Environment is all about. Beginners and more experienced users can both easily utilize this Arduino software. It is used to create interactive prototypes and begin with robotics and electronics programming. (sourced: raypcb.com) Tags:

There are many factors that can contribute to your next elevator malfunction/breakdown, did you know what they are? Be proactive and take preventative steps to minimize errors with your elevator system. Regular inspection is the first step to ensure a smooth and reliable operation. Routine maintenance and thorough inspections combined can significantly increase productivity and eliminate down time; as well as, decrease energy consumption by up to 15%. Let's face it, no one can afford to have breakdowns or long wait times. Let's Review the Five Common Elevator Issues with necessary steps to take to find solutions: PROBLEM #1: POWER FAILURE Since elevators require a large supply of power from commercial building utility systems, voltage updates can affect motor operations, and updates to systems can even cause damage to the elevator. SOLUTION: POWER QUALITY SURVEY Power quality surveys can uncover common faults like under/over voltage. Infrared thermography, for instance, measures extreme temperature fluctuations, helping to identify potential issues before they cause an expensive system failure; fuses running hot are much more easily seen using infrared technology. (sourced: ien.com) PROBLEM #2: WORN SHEAVES Worn sheaves place excess wear on ropes, in turn further increasing the level of wear on the sheaves. Ideally, proper inspection will prevent this from occurring, but once it does begin, damage is inevitable. SOLUTION: REGROOVING Either replacing or regrooving sheaves can help prevent premature hoist rope failure, so it’s important to check groove profiles in order to ensure a proper fit between sheaves and ropes. Magnetic standard tools and a straight edge can help you visually check wear on grooves. (sourced: ien.com) PROBLEM #3: CONTAMINATION With wear comes the release of small metal particles into the oil, which interferes with elevator system functioning. Improper lubrication or worn-out seals can also interfere with proper functioning. SOLUTION: OIL AND LUBRICATION ANALYSIS To ensure your elevator isn’t affected by these contaminations, a proper analysis should be completed, in which you check for certain properties in the oil that can indicate contamination or motor wear. For instance, a high level of bronze in gear case oil can mean premature wear has occurred on the gear’s crown. Or, a high level of aluminum in a hydraulic tank can mean wear has occurred on the pump housing. (sourced: ien.com) PROBLEM #4: BEARING MALFUNCTION OR LOUD BEARINGS More than 50% of all motor failures can be traced back to bearing malfunction, and vibrations within the motor can result in noisy bearings. Although variable frequency drives can help decrease the motor’s energy use, they can also introduce common mode current — a byproduct that increases vibrations to hazardous levels. SOLUTION: INDUCTIVE ABSORBERS An inductive absorber, CoolBLUE can absorb these currents and provide protection from potential breakdowns. This absorber also ensures all grounds are connected and secure, minimizing issues from electrical noise on the ground that can trip out systems. (sourced: ien.com) PROBLEM #5: MISALIGNED MOTOR DRIVE

Shaft alignment is critical when another piece of equipment is coupled to an electric motor, as improper alignment can cause wear on motor bearings. SOLUTION: LASER MEASURING Shaft alignment can be detected through the use of laser measuring equipment, or simply employing a straight edge and string. The need for alignment can be eliminated altogether, however, by purchasing a geared machine with a flange-mounted motor, which doesn’t require aligning if the machine is disassembled. (sourced: ien.com) Tags:

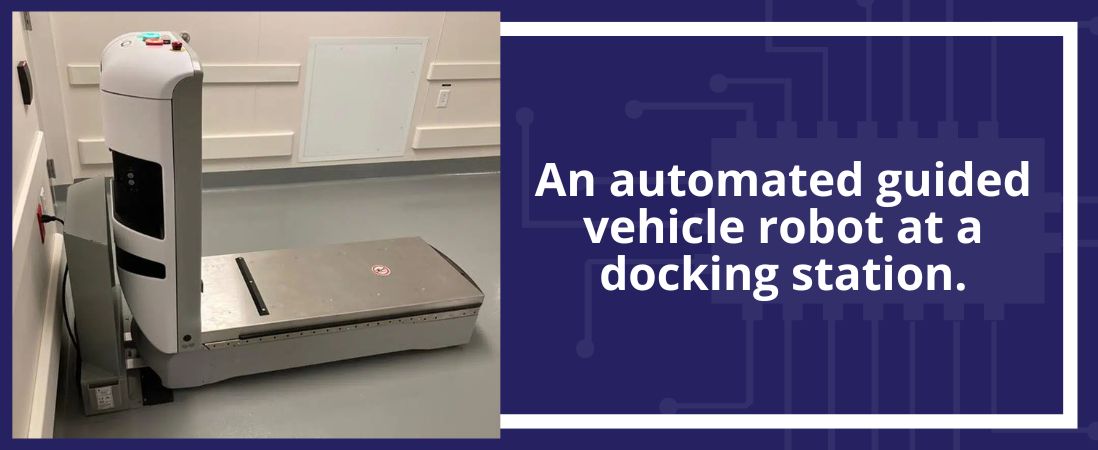

Photo: FGtrade via GettyImages Finally... a robot that can place elevator calls and transit between floors. "Advances in Application Programming Interfaces (APIs) paved the way for companies like TK Elevator (TKE) to offer robot-elevator APIs to their customers. These APIs allow robots to operate elevators via software that interfaces directly with the elevator controller. While TKE has integrated its elevators with various third-party systems for decades — including robots and autonomous vehicles — these integrations were custom-designed to be discretely wired into elevator control systems. They could be labor- and material-intensive, and prone to failure if not properly maintained." (sourced: elevatorworld.com) "In 2018, the OEM released its inaugural, standard robot-elevator API, the result of a successful pilot program that involved hospitality robots at a San Francisco hotel in 2017. Now, the technology is being integrated into the new Calgary Cancer Centre (CCC) at Foothills Medical Centre, set to open in 2023 and operated by Canada’s Alberta Health Services (AHS) in the city of Calgary." TKE Head of Digital Services Jon Clarine says: The [San Francisco] deployment was very similar to that of the [CCC]. However, the robot use was different. At [CCC] they will be used for delivery and hospital operations. Once the robot system is programmed to communicate with our API, the implementation in the building is relatively simple: An ethernet connection is established between the robot server and the elevator controller, and the rest is software.” (sourced: elevatorworld.com) "Through software, robots can ‘talk’ to elevators to place elevator calls and transit floors without the expense and complexity of discrete wiring or robotic arms, Clarine says. He observes that robots — often looking more like a piece of machinery than R2-D2 in a hospital or hotel setting — use elevators a bit differently than humans. Some move slower than humans or are programmed to wait until an elevator is unloaded prior to boarding the elevator car." (sourced: elevatorworld.com) image courtesy of Government of Alberta At the new Calgary Cancer Center (CCC), TKE completed installation of approximately 30 digitally advanced elevators with this robot supervised technology. These robots will be used to complete various tasks, primarily involving transporting medical supplies throughout the facility. The Calgary's Cancer Center (CCC) 12-service elevators will feature TKE’s robot-elevator API, which promises to improve in-house logistics and increase productivity. The API will allow robots to call an elevator via Wi-Fi or 5G LTE, select a floor, then exit the elevator upon reaching its destination. TKE observes: Using Machine Vision, a robot can determine if an elevator has enough room or it’s too full to accommodate a robot. The interface also informs the elevator system when to open the doors and adjust door dwell times to ensure the smoothest journey possible for the robot. The robotics interface can also be used for purposes such as housekeeping and security.” (sourced: elevatorworld.com) image courtesy of Dialog Design "Remote technology goes beyond elevators. TKE pioneered computer vision on escalators where it is used to detect unsafe activity such as someone leaning over the handrail or a child running in the opposite direction of travel. The system can then alert building security or slow the unit down to minimize injury risk. Remote capability extends beyond robots at the Calgary Cancer Center, as well. Three of its service elevators are designed to be remotely controlled when moving dangerous materials such as nitrogen, meaning employees are no longer exposed to such materials. TKE has also installed a remotely activated "code blue" function on a group of elevators that can be used to quickly transport patients upon arrival at the Cancer Center." (sourced: elevatorworld.com) Drawback

Robot Elevator APIs could be labor- and material-intensive, and prone to failure if not properly maintained. Some of these robots can move slower than humans. Solution These Robot Elevator APIs could place elevator calls and transit between floors. The robotics interface can also be used for purposes such as housekeeping and security. In addition, these elevators use computer vision to detect objects and activities to improve dispatching and safety. #elevators #projectmanagement #buildings #technology #innovative #elevatorrepair #robotics #robots Tags:

Photo: 1971yes via GettyImages Ding! Elevator going up. Perhaps you've been in an elevator but haven't noticed the strength, mechanics and technicality of the process that it takes to keep one active and running smoothly. In 236 before the common era, Archimedes hooked his famous pulleys to the top of a big wooden box and began to pull; this became the first elevator to be born named Eureka. Simple yet effective, this elevator was made of locally sourced, sustainably produced materials, his person-powered invention is the distant ancestor of a new crop of eco-friendly elevators now adjoining with the growing green-building market. Did you know? Some estimates project that buildings consume about 40% of the world's energy, and elevators account for between 2% and 10% of a building's energy use. The leading elevator manufacturers are rising up to get those numbers down. (sourced: asme.org) Energy consumption of the elevator contributes to it's green eco-friendly properties. In addition, the materials used in the elevator, the process and technologies that are involved are also a huge factor. What may not cross your mind is the choices of interior paints, flooring, lighting, control panels and HVAC systems in the elevator system. All of which these elements contribute valuable properties to a building's overall score for LEED accreditation by the U.S. Green Building Council. What is LEED? LEED is a third-party green building certification program and the globally recognized standard for the design, construction and operation of high-performance green buildings and neighborhoods. The rating system approach focuses on efficiency and leadership to deliver the triple bottom line returns of "people, planet and profit." Appropriate for all building types and phases, including new construction, interior fit-outs, operations and maintenance, and core and shell, LEED gives building owners and operators the tools they need to have an immediate and measurable effect on the performance of their spaces. By promoting a whole-building approach to sustainability, LEED recognizes achievements in location and planning, sustainable site development, water savings, energy efficiency, materials selection, waste reduction, indoor environmental quality, innovative strategies and attention to priority regional issues. (sourced: usgbc.org) What is MRL Technology? In the mid-1990s, machine-room-less (MRL) technology was one of the biggest advances in elevator design since they went electric a century before. Miniaturization has made it feasible to house the MRL machinery right in the elevator shaft rather than in a costly rooftop machine room. Incorporating a gearless traction design, MRL elevators in some cases can use up to 80% less energy than hydraulic lifts, without the expense and environmental headaches of oil-filled underground hydraulic cylinders. KONE, Inc. introduced the first MRL elevator and places so much stock in the technology that the company discontinued manufacturing hydraulic elevators altogether. Its EcoSpace MRL elevator design incorporates a low-friction, gearless hoisting apparatus that prevents wear and reduces energy consumption by half compared to a geared system. A machine-room-less elevator system by Otis, the Gen2 system, is scalable to save energy in a range of building heights. It too aspires to 50% energy reduction over earlier systems, with the added green bonus of lubrication-free operation thanks to polyurethane coated-steel belts, gearless machine, and roller guides. (sourced: asme.org) Regenerative Drive Systems Recover Energy Regen Drive Systems would normally be dissipated as heat, send it back into the buildings' electrical system as ways to recover energy. This technology produces power for lighting and air conditioning; it also saves money by reducing the need for machine-room cooling. Regenerative drives reduce power consumption during peak periods, contributing to a building's overall operational bottom line. (sourced: asme.org) Drawback Elevator technology and mechanics are so advanced and will no longer be as eco-friendly as they were first introduced. Solution Elevator companies' major goal for the future of eco-friendly elevator technology is to cut down on light loads through precision traffic control, management of interior lighting and other energy-burning factors. Novel computerized systems help reduce the number of light-load trips while ensuring that there are enough elevators in operation to provide fast service. Schindler's (Morristown, NJ) systems offer an Energy Control Option (ECO) mode that switches unused elevators into standby. If waiting times become too long, the system will activate additional cabs to meet the need. ThyssenKrupp (Memphis, TN) says its Destination Dispatch system improves handling capacity by 15-30%. The system monitors and controls the amount of current delivered to the motor, ensuring the correct level to provide to keep the motor running at full speed. As a result, the motor is protected from peak over-currents, potential overload and sudden power surges. (sourced: asme.org) #elevators #projectmanagement #buildings #technology #innovative #gogreen #elevatorrepair

Tags:

|

AuthorChristopher K. Categories |

Miltronics Inc. © Copyright 2022. All Rights Reserved.

Cookies Policy | Privacy Statement

Cookies Policy | Privacy Statement

Useful Links |

Browse Our Site |

Contact Info |

Services |